From Raw Material to Market Leader: The Al Furidi-SABIC Success Story

aza. 29, 2024

In Al Kharj's advanced industrial zone, Al Furidi's strategic alliance with SABIC exemplifies manufacturing excellence in the Middle East's plastic industry. This collaboration merges SABIC's premium HDPE materials with Al Furidi's state-of-the-art injection moulding technology, creating a powerhouse in industrial plastic manufacturing. The partnership leverages dual ISO certifications - ISO 14001:2015 and ISO 50001:2018 - demonstrating commitment to environmental stewardship and energy efficiency .

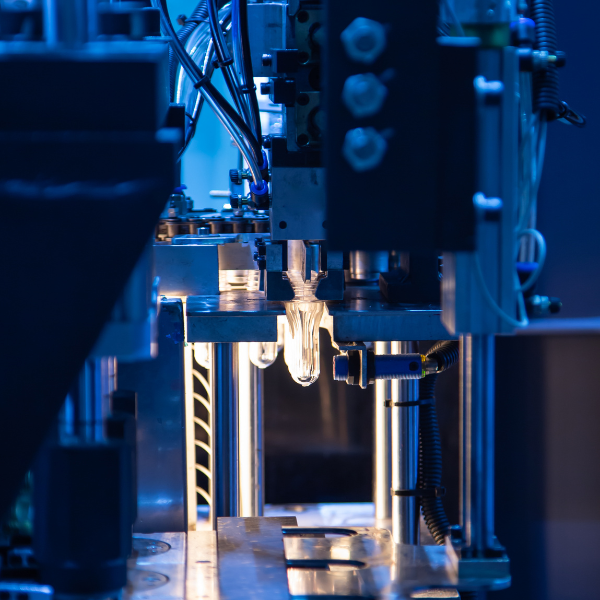

The injection machines hall represents the cornerstone of Al Furidi's manufacturing excellence. Advanced servo-driven systems and multi-zone temperature control ensure precise material processing for industrial-grade plastic products. The facility's sophisticated control systems enable microscopic control over injection processes, while maintaining optimal material flow throughout the mold cavity.

- Automated production systems with real-time monitoring

- Multi-zone temperature control for optimal processing

- Advanced material handling systems

- Precision injection moulding technology

- Quality control integration at every stage

Premium HDPE materials undergo comprehensive selection processes, ensuring optimal performance across diverse industrial applications. Material properties are engineered to meet specific requirements:

- UV stability rating: High resistance for outdoor applications

- Impact strength: Exceeds industry standards

- Chemical resistance: Superior protection against corrosive elements

- Temperature tolerance: -40°C to +80°C

- Processing temperature range: 190°C to 280°C

The manufacturing facility demonstrates Industry 4.0 leadership through comprehensive IoT sensor networks. AI-powered quality control systems analyze real-time data streams, identifying potential issues before they impact product quality. The facility maintains:

- 40% reduction in production cycle times

- 30% improvement in energy efficiency

- 50% decrease in quality deviations

- 25% increase in production capacity

The Al Furidi manufacturing facility delivers an extensive range of industrial solutions powered by advanced injection moulding technology. The facility's ISO-certified manufacturing processes ensure consistent quality across all product categories:

- Heavy-duty plastic pallets with a load capacity of up to 1,500 kg

- Industrial storage bins with reinforced construction

- Stackable storage systems for warehouse optimization

- Custom storage solutions for specific industry requirements

- Premium water tanks (1,000L - 3,000L capacity)

- UV-stabilized HDPE construction

- Food-grade material compliance

- Enhanced durability for extreme conditions

- Traffic management solutions

- Industrial safety equipment

- Structural covers and barriers

- High-visibility safety products

Environmental stewardship stands at the core of Al Furidi's manufacturing philosophy, validated through dual ISO certifications. The facility implements:

- Advanced energy monitoring systems

- Optimized production scheduling

- Heat recovery systems

- Smart lighting solutions

- Closed-loop material recycling

- Water conservation systems

- Waste reduction protocols

- Sustainable packaging solutions

The injection machines hall maintains rigorous quality standards through:

- Material composition analysis

- Dimensional accuracy verification

- Load capacity testing

- Environmental stress testing

- ISO 14001:2015 environmental management

- ISO 50001:2018 energy management

- International quality benchmarks

- Industry-specific compliance

Al Furidi's ISO-certified manufacturing facility serves diverse international markets with exceptional precision and reliability. The advanced injection machines hall, validated by ISO 14001:2015 and ISO 50001:2018 certifications, enables customized solutions for various industries:

- Middle East industrial sector requirements

- European quality standards compliance

- Asian market specifications

- African market adaptations

- Industrial storage solutions

- Security and safety solutions

- Construction industry solutions

- Water and beverage storage solutions

The facility's commitment to technological advancement includes:

- Advanced material handling systems

- Automated quality verification

- Smart production scheduling

- Energy optimization protocols

- Market-driven design solutions

- Enhanced material properties

- Application-specific innovations

- Sustainable product engineering

Strategic initiatives ensure sustained market leadership through:

- Advanced automation systems

- Real-time production monitoring

- Quality control innovation

- Smart factory solutions

- Global partnership expansion

- Industry sector diversification

- Regional market penetration

- Customer solution innovation

Through this strategic partnership and advanced manufacturing capabilities, Al Furidi continues to set industry standards in plastic manufacturing while serving global B2B markets with premium HDPE solutions.

Contact Excellence

Experience manufacturing innovation at our facility:

Location

Street 59, Al Kharj Industrial Cities Authority

Riyadh, Saudi Arabia

Contact Details

Phone: +966 50 883 4433

Email: info@alfuridiplast.com

Your email address will not be published. Required fields are marked *