From Raw Material to Market Leader: The Al Furidi-SABIC Success Story

aza. 29, 2024

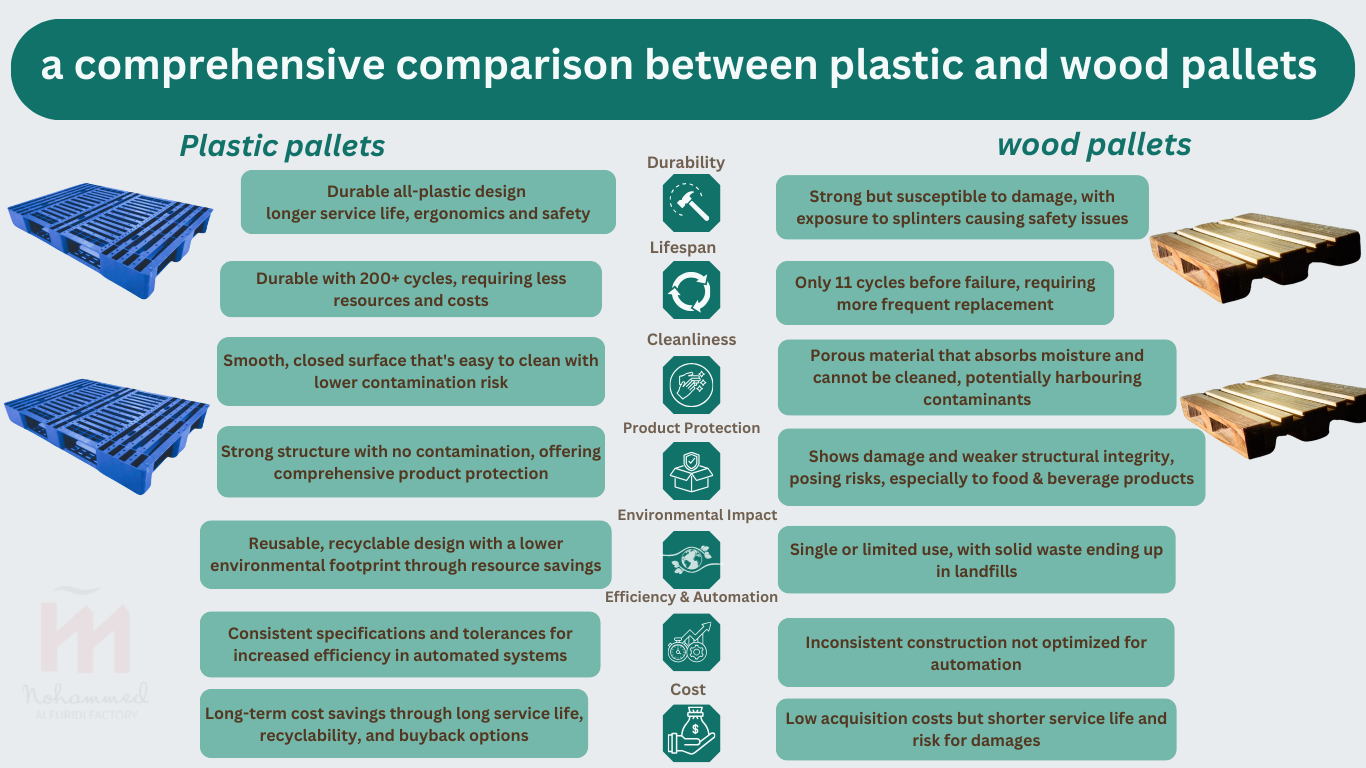

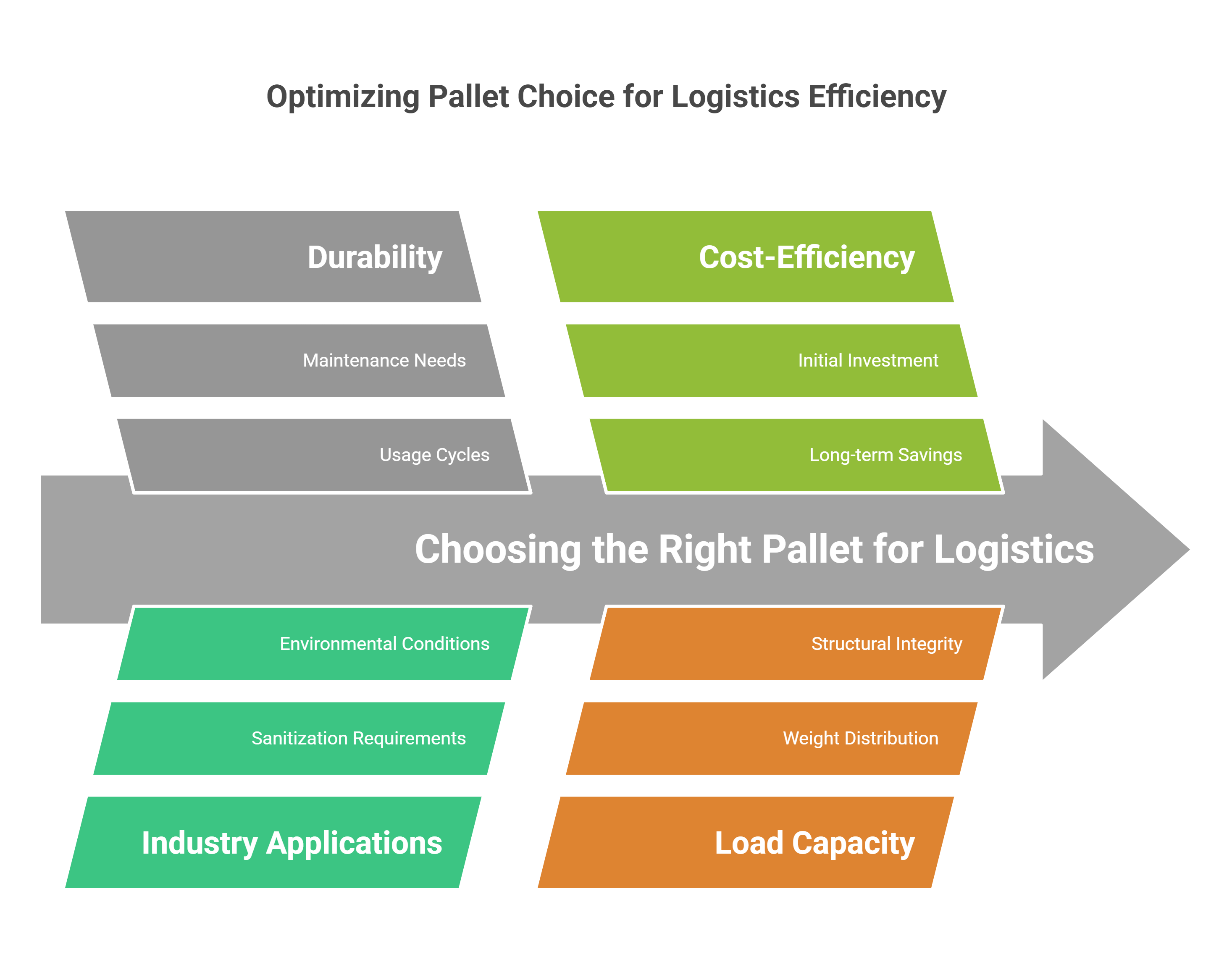

In today's rapidly evolving supply chain landscape, choosing between HDPE and wooden pallets represents a pivotal decision for modern businesses. At Al Furidi Plastic Industries, we understand that material-handling equipment forms the backbone of efficient logistics operations. The transformation from traditional wooden pallets to advanced HDPE solutions marks a significant shift in how industries approach their material handling challenges.

The evolution of pallet technology reflects the changing demands of modern supply chains. Traditional wooden pallets, while familiar, increasingly struggle to meet the exacting requirements of automated systems and stringent hygiene standards. HDPE pallets represent a quantum leap in material handling technology, offering unprecedented durability and consistency in performance.

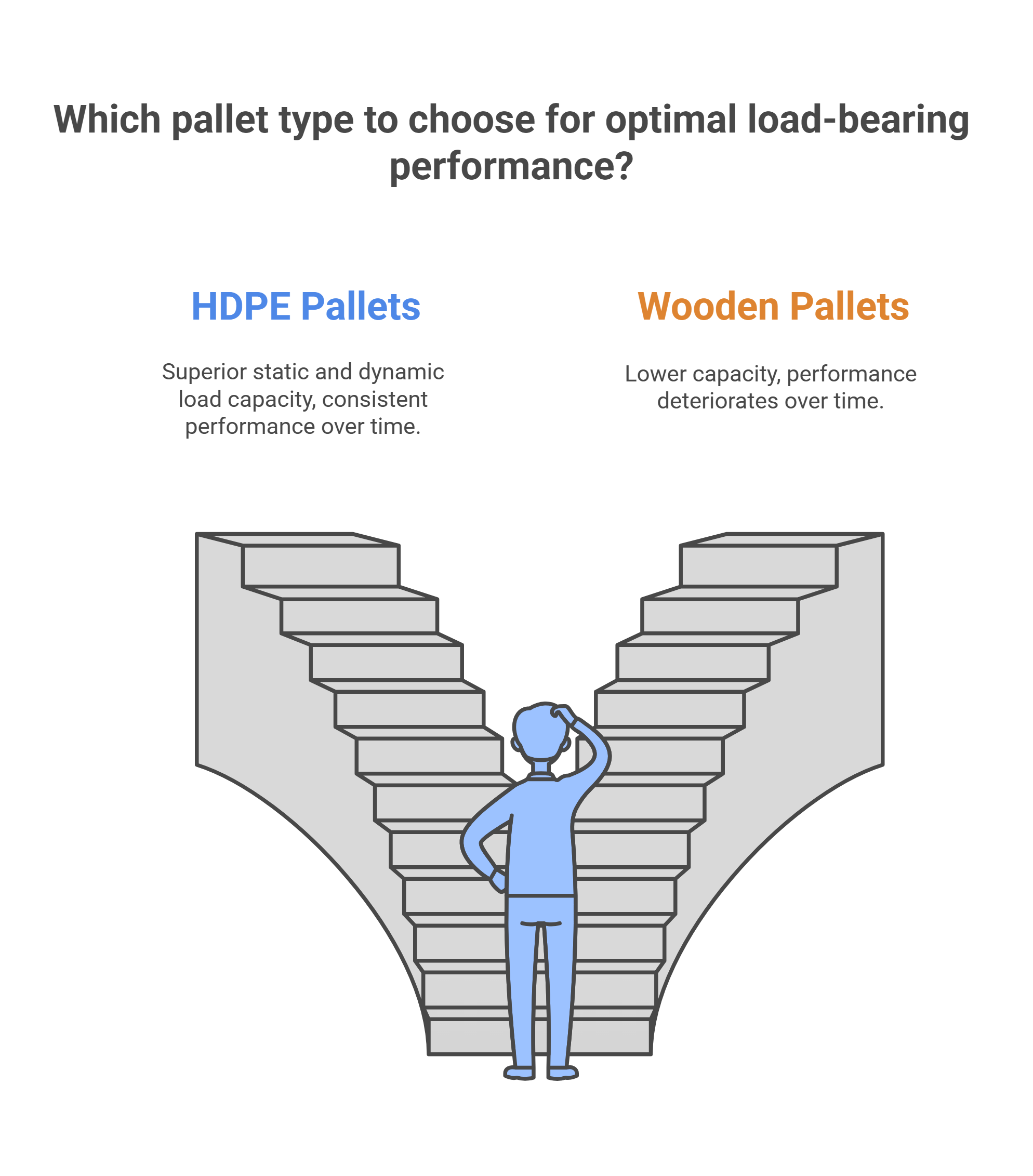

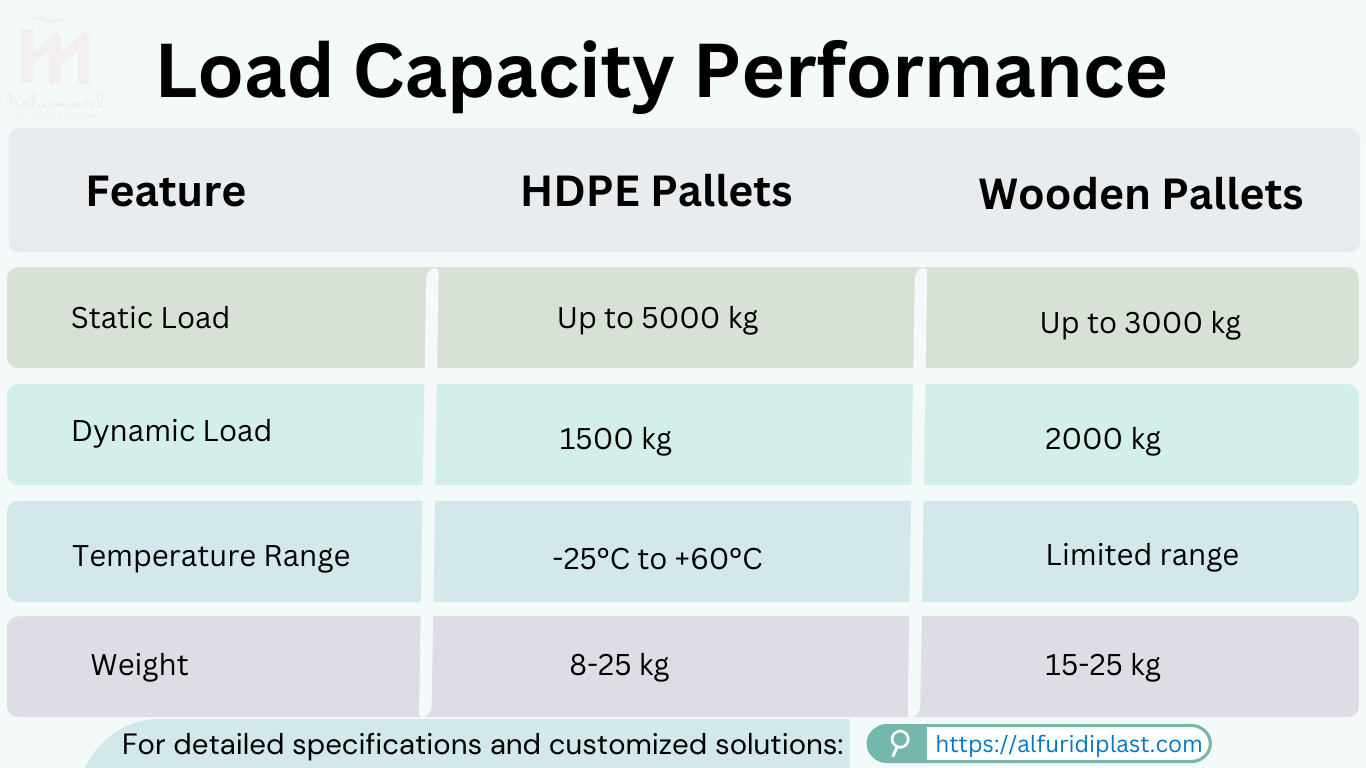

The comparison between HDPE and wooden pallets reveals striking differences in load-bearing capabilities. Static load performance tests demonstrate that HDPE pallets can support up to 5,000 kg, significantly outperforming traditional wooden alternatives. Dynamic load capabilities maintain consistent performance throughout their lifecycle, unlike wooden pallets that deteriorate over time.

HDPE pallets revolutionize material handling with their lightweight design, typically weighing 15-16 kg compared to wooden pallets' 30-70 pounds. This weight reduction translates into substantial operational benefits, from reduced transportation costs to improved ergonomics for manual handling operations.

Durability and Lifespan

Modern HDPE pallets demonstrate remarkable longevity with over 200 use cycles compared to wooden pallets' mere 11 cycles. This dramatic difference in service life transforms the economics of material handling operations. Al Furidi's advanced manufacturing processes ensure each pallet maintains structural integrity throughout its extended lifecycle, delivering consistent performance in demanding industrial environments.

Moisture and Environmental Resistance

HDPE pallets revolutionize material handling through complete moisture immunity. Unlike wooden alternatives that absorb water and deteriorate, our plastic pallets maintain dimensional stability and structural integrity in wet conditions. This moisture resistance eliminates concerns about mould growth, bacterial contamination, and structural degradation common with wooden pallets.

Safety and Compliance

The unibody construction of HDPE pallets eliminates workplace hazards associated with traditional wooden pallets. No splinters, protruding nails, or broken boards means enhanced worker safety and reduced risk of product damage. Our pallets comply with stringent safety standards, offering superior chemical resistance and fire safety characteristics.

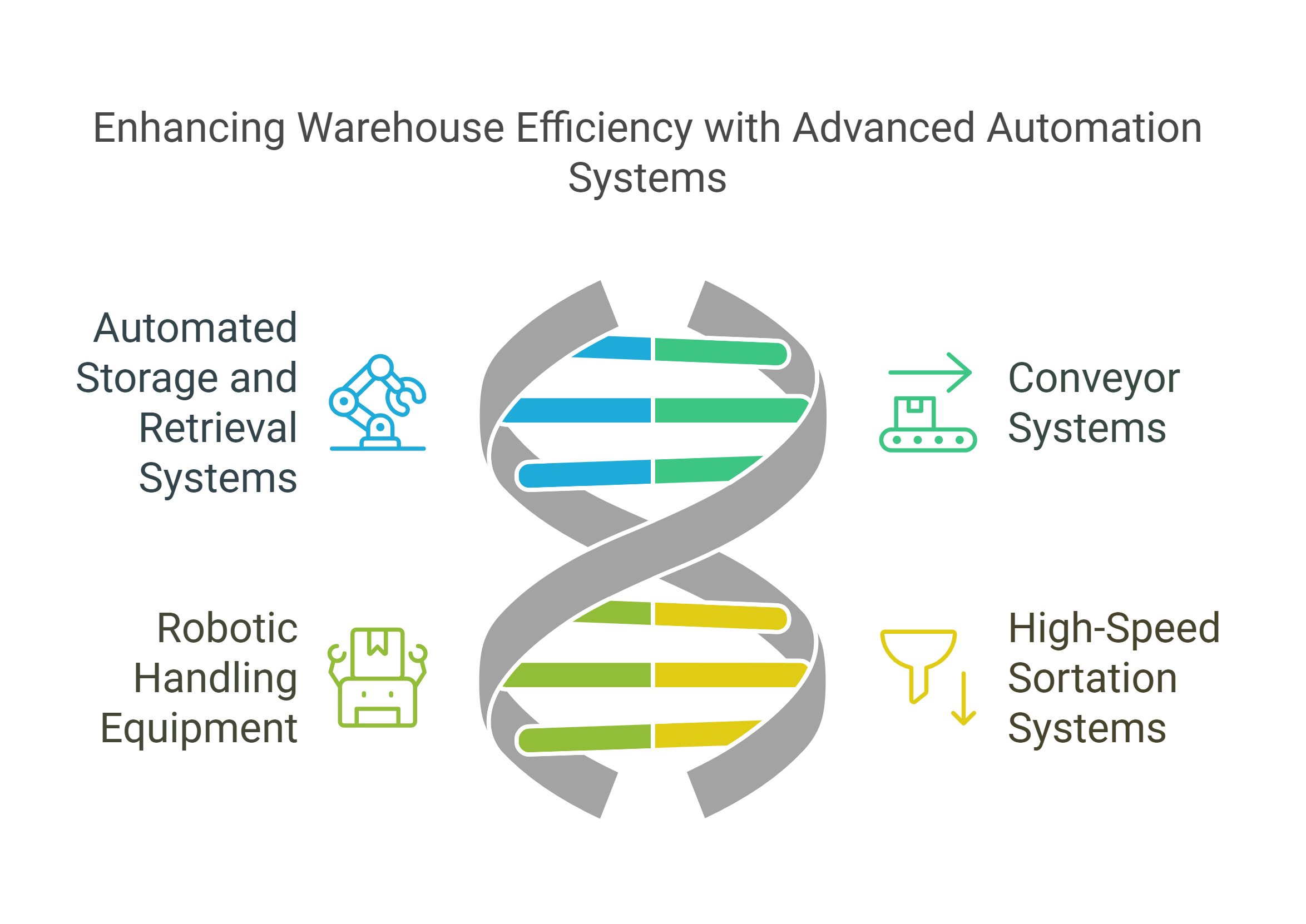

Automation and Equipment Integration

In modern automated facilities, HDPE pallets demonstrate unparalleled compatibility with advanced handling systems. Consistent dimensions and smooth surfaces ensure reliable performance in:

- Automated Storage and Retrieval Systems (AS/RS)

- Conveyor systems

- Robotic handling equipment

- High-speed sortation systems

Cleanliness and Contamination Control

The non-porous surface of HDPE pallets creates an insurmountable barrier against contamination. Unlike wooden pallets that harbour bacteria and absorb spills, our plastic pallets maintain hygiene standards crucial for:

- Food and beverage operations

- Pharmaceutical manufacturing

- Clean room environments

- Chemical processing facilities

In the competitive logistics landscape, HDPE pallets deliver significant cost advantages. Their lightweight design, typically 15-16 kg compared to wooden pallets' 30-70 pounds, translates into measurable fuel savings and increased payload capacity. Each truckload can accommodate more product weight, optimizing transportation efficiency and reducing the total cost per shipment.

Modern HDPE pallets exemplify circular economy principles through:

- Complete recyclability at end-of-life

- Reduced carbon footprint in transportation

- Extended service life of 200+ cycles

- Zero waste through material recovery

- Lower environmental impact per usage cycle

While initial investment in HDPE pallets may be higher, the long-term financial benefits are substantial:

- Higher upfront costs balanced by extended lifespan

- Reduced replacement frequency

- Lower maintenance requirements

- Decreased product damage claims

HDPE pallets demonstrate superior value through:

- Extended service life beyond 200 cycles

- Minimal maintenance costs

- Reduced operational expenses

- Enhanced protection for transported goods

The implementation of HDPE pallets transforms warehouse operations through:

- Reduced handling time

- Optimized storage space utilization

- Improved process integration

- Enhanced automation compatibility

- Consistent performance metrics

HDPE pallets excel in specialized industries:

- Food and beverage operations requiring strict hygiene

- Pharmaceutical manufacturing with contamination controls

- Chemical processing with corrosion resistance needs

- Clean room environments demanding pristine conditions

Looking ahead, HDPE pallets continue to evolve with:

- IoT integration capabilities

- Enhanced tracking features

- Improved material science applications

- Advanced automation compatibility

Modern logistics demands precision in material handling, and the choice between HDPE and wooden pallets significantly impacts operational efficiency. Here's a detailed comparison of key specifications:

- HDPE Pallets: 200+ usage cycles

- Wooden Pallets: Approximately 11 cycles

- Maintenance Requirements: Minimal for HDPE vs Regular for wood

- Moisture Resistance: Complete for HDPE vs Susceptible for wood

HDPE pallets excel in:

- Food and pharmaceutical industries requiring sanitization

- Automated warehousing systems

- Chemical storage applications

- Temperature-controlled environments

While initial investment is higher for HDPE pallets, long-term benefits include:

- Reduced replacement frequency

- Lower maintenance costs

- Decreased product damage

- Improved operational efficiency

This comparison demonstrates HDPE pallets' superior performance in modern industrial applications, particularly where hygiene, durability, and automation compatibility are crucial factors.

For detailed specifications and customized solutions, visit https://alfuridiplast.com.

Through these comprehensive advantages, HDPE pallets continue to set new standards in material handling efficiency and operational excellence.

Experience manufacturing innovation at our facility:

Street 59, Al Kharj Industrial Cities Authority

Riyadh, Saudi Arabia

Phone: +966 50 883 4433

Email: info@alfuridiplast.com

- ISO 14001:2015 Environmental Management

- ISO 50001:2018 Energy Management

Visit our facility to witness firsthand the revolutionary capabilities of our manufacturing technology and discover why Al Furidi continues to lead the way in plastic manufacturing innovation.

Your email address will not be published. Required fields are marked *