From Raw Material to Market Leader: The Al Furidi-SABIC Success Story

aza. 29, 2024

Step into the future of manufacturing excellence where Al Furidi's FTN-2800 and SE-2200 stand as technological marvels, revolutionizing the plastic manufacturing landscape. These cutting-edge machines represent more than mere equipment – they embody the pinnacle of engineering innovation and manufacturing precision.

Breaking Industry Boundaries

The FTN-2800 emerges as a groundbreaking injection molding system, featuring advanced servo-driven technology and unprecedented precision control. Its innovative design incorporates state-of-the-art parallel processing capabilities, enabling simultaneous operations that slash production times while maintaining exceptional quality standards.

Meanwhile, the SE-2200 showcases advanced engineering precision in CNC turning technology. Its sophisticated 30° slanted one-piece bed structure maximizes rigidity and machining accuracy, setting new benchmarks in manufacturing precision.

The FTN-2800 and SE-2200 represent significant advancements in manufacturing technology, pushing the boundaries of what's possible in plastic production and CNC turning respectively.

The FTN-2800 injection moulding system stands out as a game-changer in the industry, incorporating cutting-edge features that enhance both efficiency and quality

Advanced Servo-Driven Technology: This system provides precise control over the injection process, resulting in higher accuracy and consistency in part production.

Parallel Processing Capabilities: By enabling simultaneous operations, the FTN-2800 significantly reduces production times without compromising on quality.

Multi-Zone Temperature Control: This feature ensures optimal temperature distribution throughout the mould, leading to improved part quality and reduced defects.

Intelligent Pressure Monitoring: Real-time pressure monitoring allows for immediate adjustments, maintaining consistent part quality throughout production runs.

Real-Time Quality Assurance: Integrated quality control protocols continuously monitor the production process, ensuring that each part meets stringent quality standards

The SE-2200 CNC turning centre showcases Al Furidi's commitment to engineering excellence:

30° Slanted One-Piece Bed Structure: This innovative design maximizes rigidity and stability, resulting in superior machining accuracy even during high-speed operations.

High-Speed Performance: With a maximum spindle speed of 4,500 RPM, the SE-2200 delivers rapid and precise turning operations.

Enhanced Vibration Absorption: The increased ground area of the machine provides better vibration dampening, ensuring consistent quality in machined parts.

Roller LM Guideway System: This high-speed linear motion system reduces non-cutting time while maintaining high rigidity, improving overall productivity.

Versatile Machining Capabilities: The SE-2200 can handle a maximum turning diameter of 350mm, making it suitable for a wide range of applications

Together, the FTN-2800 and SE-2200 form a powerful duo in Al Furidi's manufacturing arsenal. The FTN-2800's advanced injection moulding capabilities complement the SE-2200's precision turning abilities, allowing for the production of complex plastic components with tight tolerances and excellent surface finishes. This technological synergy positions Al Furidi at the forefront of plastic manufacturing, enabling the company to meet the demanding requirements of various industries, from automotive and aerospace to consumer electronics and medical devices. By investing in these cutting-edge machines, Al Furidi demonstrates its commitment to innovation and quality, setting new standards in the plastic manufacturing industry and solidifying its position as a technological powerhouse.

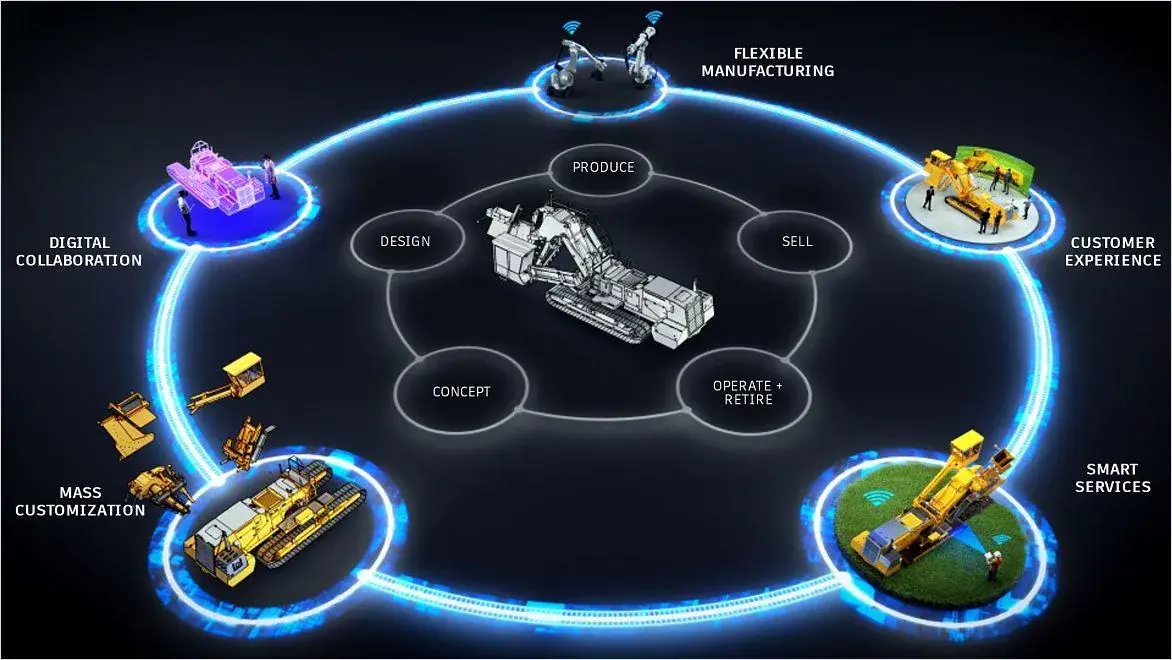

The integration of smart manufacturing systems transforms traditional production processes into intelligent, data-driven operations. Our automated production systems leverage advanced robotics and AI-powered quality control, ensuring unprecedented precision and consistency.

Al Furidi has embraced smart manufacturing technologies to transform its production processes:

This integration of smart technologies allows Al Furidi to:

Enhance flexibility and responsiveness to market demands.

At the core of Al Furidi's manufacturing capabilities are the FTN-2800 injection moulding system and SE-2200 CNC turning centre, working in seamless harmony:

This advanced production ecosystem enables Al Furidi to achieve exceptional precision, efficiency, and quality in its manufacturing processes. The seamless integration of these cutting-edge machines with smart manufacturing technologies positions Al Furidi at the forefront of modern manufacturing excellence.

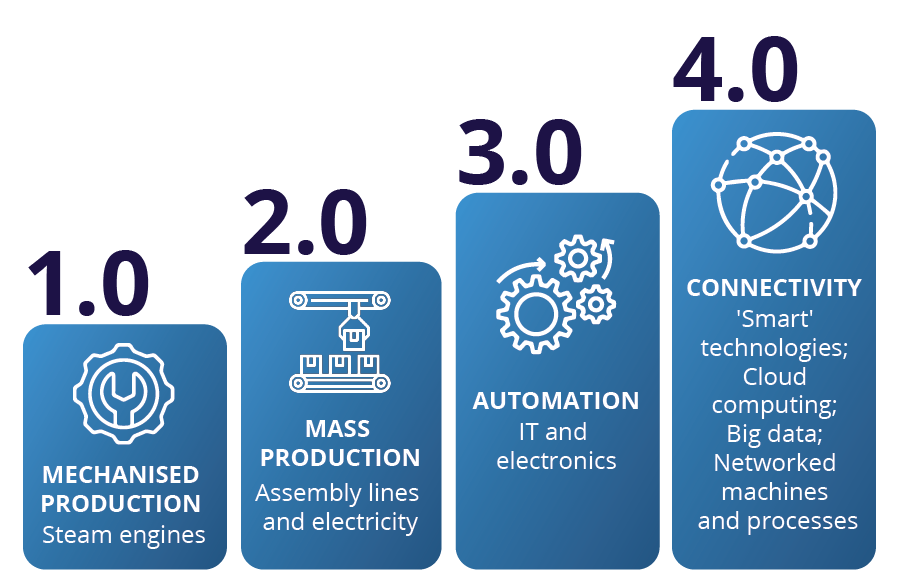

The integration of advanced technologies in Al Furidi's manufacturing processes represents a significant leap forward in quality assurance and digital transformation, aligning perfectly with Industry 4.0 principles.

The integration of cutting-edge monitoring systems transforms traditional quality control into a dynamic, predictive process. Through the SE-2200's advanced CNC capabilities, each component undergoes microscopic scrutiny, ensuring dimensional accuracy down to the micron level. This relentless pursuit of perfection is further enhanced by real-time data analytics that anticipate and prevent potential quality deviations before they occur.

Al Furidi's approach to quality control has evolved into a sophisticated, proactive system that leverages the capabilities of the SE-2200 CNC turning centre:

Microscopic Scrutiny: The SE-2200's advanced CNC capabilities enable dimensional accuracy inspection at the micron level, ensuring unprecedented precision in component manufacturing.

Real-Time Analytics: By implementing AI-driven quality control systems, Al Furidi can detect defects instantly, allowing for immediate corrective actions and preventing quality deviations before they occur.

Predictive Quality Control: Machine learning algorithms analyze production data to identify patterns and predict potential quality issues, enabling preemptive adjustments to maintain high product standards.

In the realm of Industry 4.0, our manufacturing facility stands as a testament to digital innovation. The FTN-2800's intelligent control system interfaces seamlessly with our cloud-based manufacturing execution system, creating a digital thread that weaves through every aspect of production. This unprecedented level of connectivity enables real-time optimization of manufacturing parameters, while predictive maintenance algorithms ensure maximum uptime.

Al Furidi's manufacturing facility exemplifies the core principles of Industry 4.0 through its implementation of digital technologies:

Intelligent Control System : The FTN-2800's control system is seamlessly integrated with a cloud-based manufacturing execution system, creating a comprehensive digital thread throughout the production process.

Real-Time Optimization: This high level of connectivity allows for continuous adjustment of manufacturing parameters, optimizing production efficiency and quality.

Predictive Maintenance : Advanced algorithms analyze machine data to forecast potential equipment failures, scheduling maintenance activities to maximize uptime and reduce unexpected downtimes.

Cloud Integration: By leveraging cloud technologies, Al Furidi can process and analyze vast amounts of production data, enabling more informed decision-making and process improvements.

This digital transformation not only enhances operational efficiency but also positions Al Furidi at the forefront of smart manufacturing. The seamless integration of AI, IoT, and cloud computing creates a highly responsive and adaptive production environment, capable of meeting the evolving demands of modern manufacturing.

Certified Environmental Leadership

Al Furidi's commitment to environmental leadership is exemplified by its dual ISO certifications in ISO 14001:2015 and ISO 50001:2018, demonstrating a comprehensive approach to environmental management and energy efficiency.

The SE-2200's energy-efficient design complements this commitment, utilizing smart power management to reduce consumption during non-peak operations.

Al Furidi's technological prowess, exemplified by the FTN-2800 and SE-2200 systems, has indeed positioned the company as a global leader in plastic manufacturing. These advanced systems, combined with ISO-certified processes, create a powerful foundation for serving diverse market needs while maintaining consistent quality across international boundaries.

Consistent Quality: Advanced process control and real-time monitoring ensure consistent product quality across international boundaries.

Flexibility: The smart manufacturing ecosystem allows for rapid adaptation to changing market demands and customer preferences.

Sustainability: ISO certifications and energy-efficient technologies appeal to the growing global demand for sustainable manufacturing practices.

Competitive Advantage: The integration of Industry 4.0 technologies sets Al Furidi apart in the marketplace, offering enhanced productivity, quality, and customization capabilities.

By leveraging these advanced manufacturing systems and adhering to international standards, Al Furidi has established itself as a global leader in plastic manufacturing. The company's commitment to technological innovation, environmental responsibility, and quality excellence ensures its position at the forefront of the global manufacturing landscape, ready to meet the evolving needs of diverse markets worldwide.

Connect With Excellence

Experience the power of advanced manufacturing technology at our state-of-the-art facility:

Location

Street 59, Al Kharj Industrial Cities Authority

Riyadh, Saudi Arabia

Contact Details

Phone: +966 50 883 4433

Email: info@alfuridiplast.com

Certifications

- ISO 14001:2015 Environmental Management

- ISO 50001:2018 Energy Management

Visit our facility to witness firsthand the revolutionary capabilities of our manufacturing technology and discover why Al Furidi continues to lead the way in plastic manufacturing innovation.

Our facility stands ready to demonstrate how the FTN-2800 and SE-2200 systems can transform your manufacturing requirements into reality. From precision engineering to sustainable production methods, our team of experts looks forward to showcasing how these advanced systems can meet your specific needs.

Your email address will not be published. Required fields are marked *