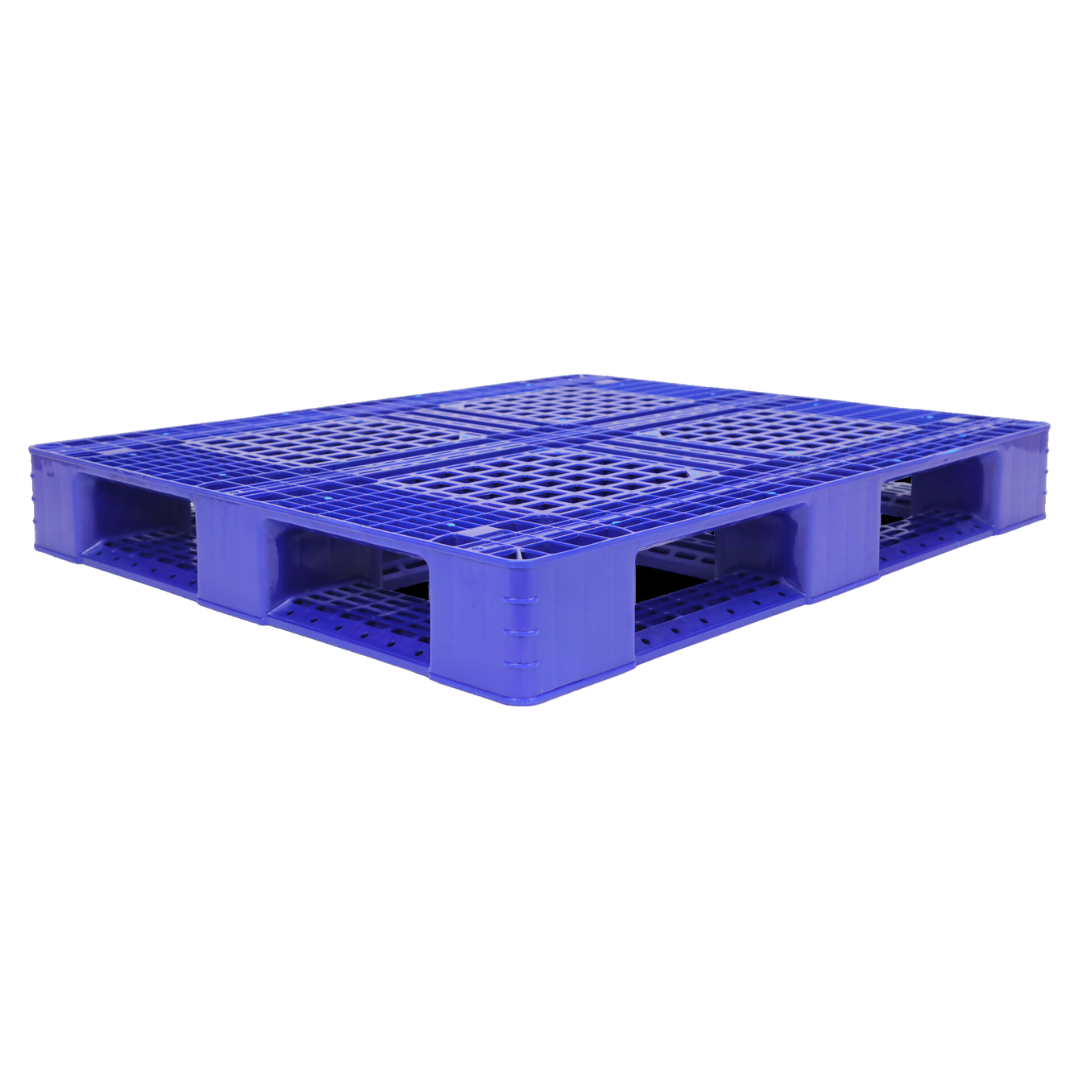

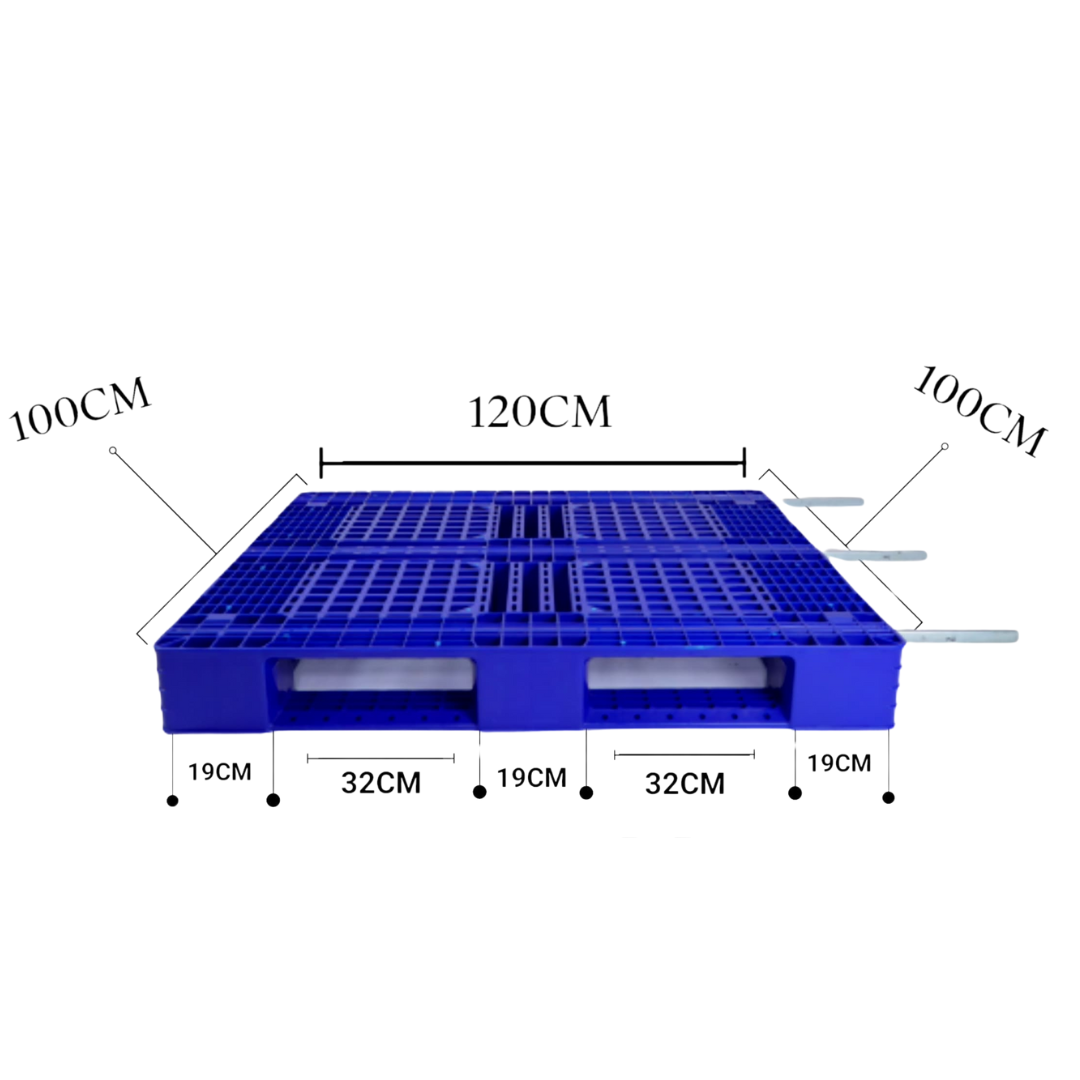

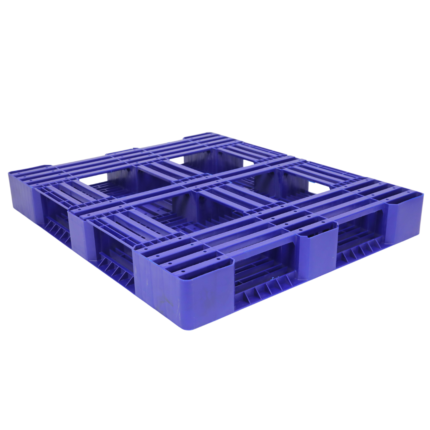

طبلية بلاستيك مقاس 1200 × 1000 × 150 ملم

ر.س0.00

اختبر الكفاءة العالية في التخزين مع طبليات مصنع محمد ناصر الفريدي للصناعات البلاستيكية الحاصلة على شهادة الآيزو. مصنعة باستخدام مواد سابك الممتازة وتحت معايير الآيزو 9001:2015، تمثل هذه الطبليات الصناعية قمة الحلول اللوجستية الحديثة .

المميزات الرئيسية

– مصنعة من مواد سابك عالية الكثافة HDPE/PP

– حاصلة على شهادة الآيزو 9001:2015

– سطح علوي مهوى للتدفق الأمثل للهواء

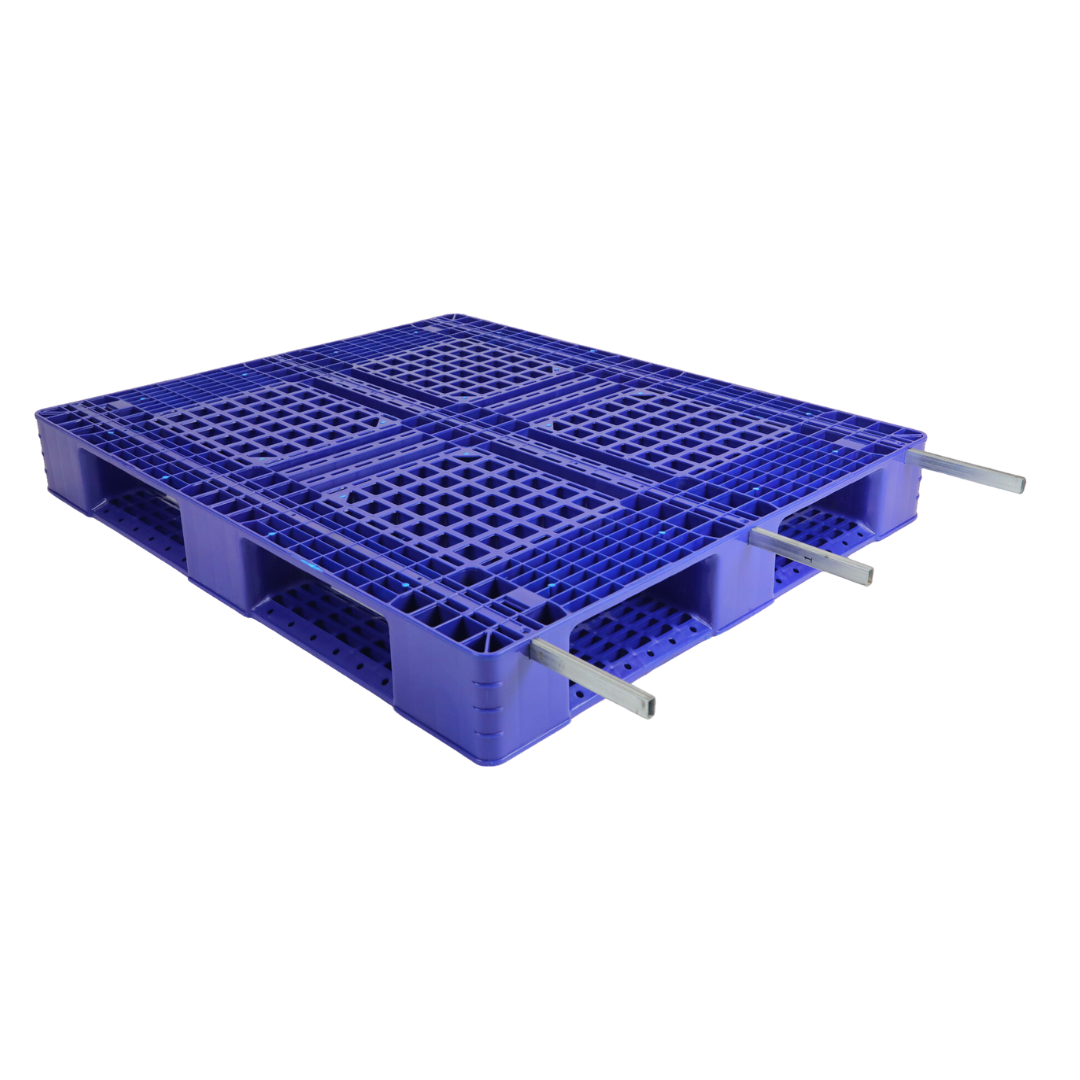

– نظام 8 قوائم انزلاقية لثبات محسن

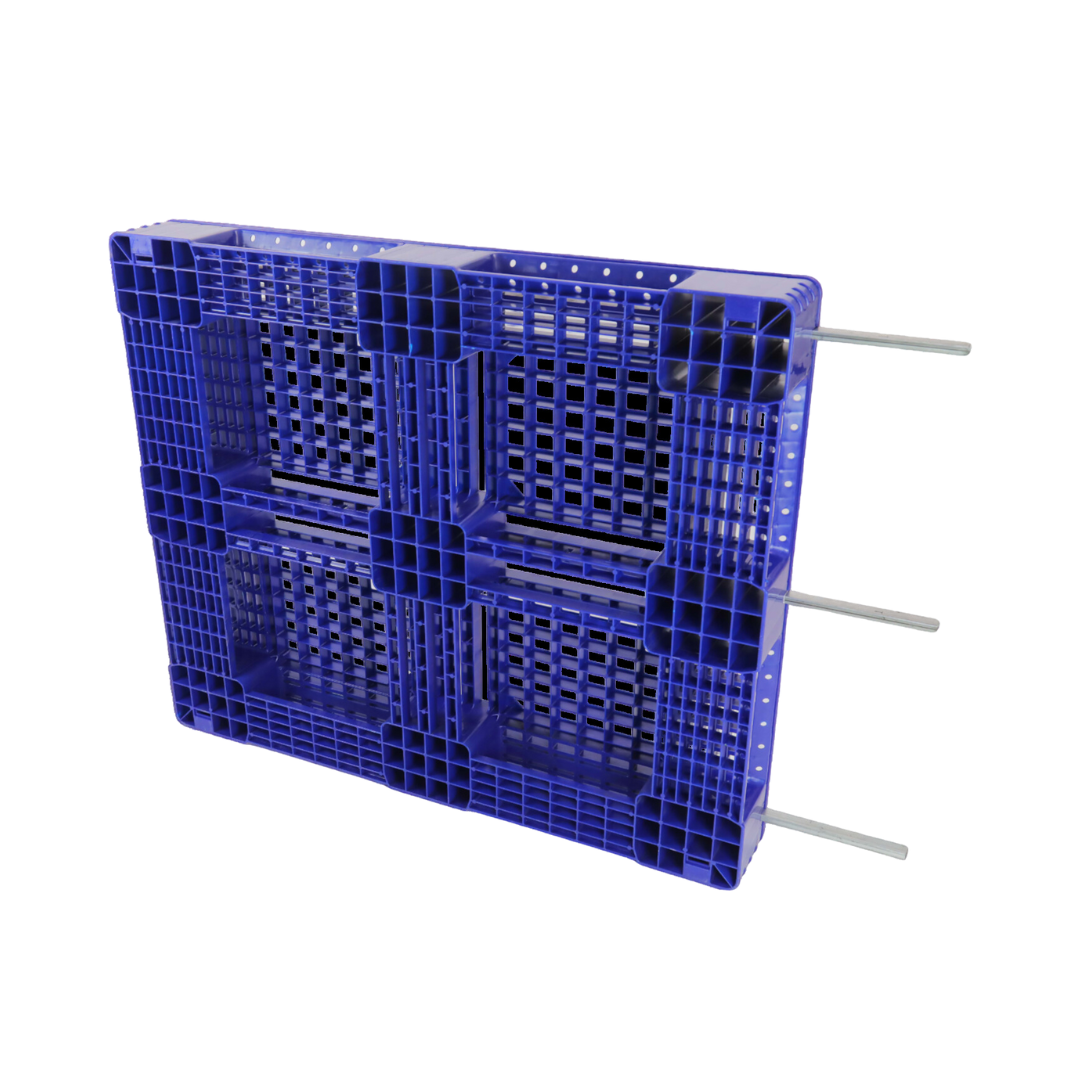

– تصميم رباعي المداخل للمناولة الفعالة

– معالجة ضد الأشعة فوق البنفسجية للاستخدام الخارجي

– مقاومة لدرجات الحرارة من -25 إلى +60 درجة مئوية

المواصفات الفنية

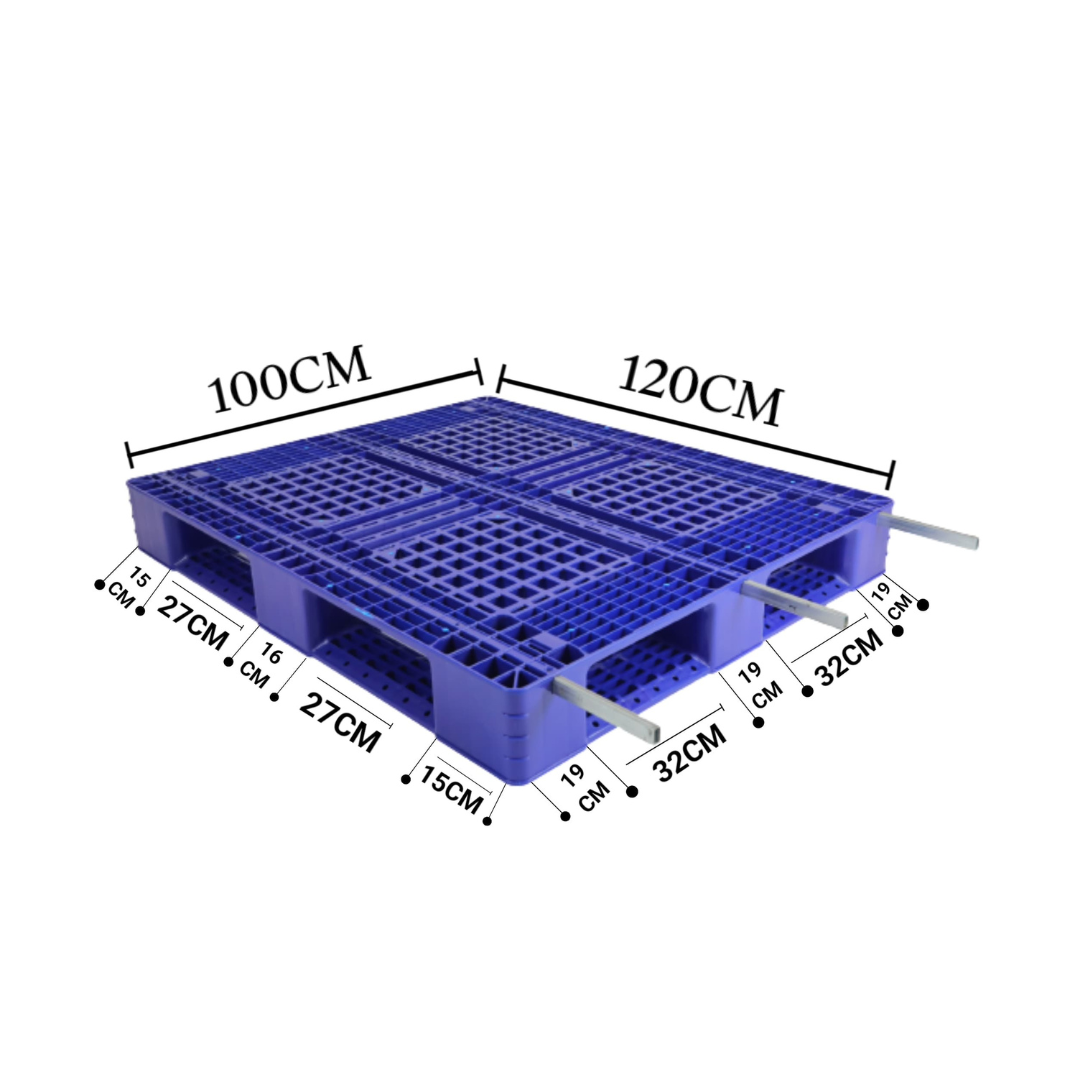

– الأبعاد: 1200 × 1000 × 150 مم

– الوزن: 16 كجم ±0.5 كجم

– قدرة التحمل :

– ثابت: 2000 كجم

– متحرك: 1000 كجم

– رفوف: 800 كجم

– المادة: بولي إيثيلين/بولي بروبلين عالي الكثافة من سابك مع مثبتات الأشعة فوق البنفسجية

– تكوين القوائم: 8 قوائم انزلاقية غير ملحومة

– نظام الدخول: رباعي الاتجاهات

– نوع السطح: تصميم علوي مهوى

المزايا الإضافية

– مقاومة عالية للصدمات

– تصميم خفيف الوزن لتحسين تكاليف النقل

– سطح مانع للانزلاق لتعزيز السلامة

– مواد قابلة لإعادة التدوير 100 %

– حل اقتصادي طويل الأمد

– مقاومة ممتازة للمواد الكيميائية والرطوبة

– سهولة التنظيف والصيانة

الطبلية البلاستيك ذات التهوية،مصممة للتعامل مع الأحمال الثقيلة بمتانة وأداء استثنائيين من الدرجة الصناعية بسطح علوي مهوى و 8 عدائين للانزلاق، مما يجعلها مثالية للبيئات الصعبة. يتم تصنيع هذه المنصة بمواد حقن عالية الكثافة من البولي إيثيلين والبولي بروبيلين ومثبتات الأشعة فوق البنفسجية، وتوفر قوة فائقة وطول العمر.

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.