From Raw Material to Market Leader: The Al Furidi-SABIC Success Story

aza. 29, 2024

In the evolving landscape of industrial logistics, entry point design represents a critical element of pallet engineering excellence. At Mohammed Nasser Al Furidi Plastic Industries Factory, ISO 9001:2015 certified manufacturing processes ensure precise dimensional control and superior load distribution characteristics across our entire pallet range. The sophisticated engineering behind each entry point configuration demonstrates our commitment to maximizing operational efficiency while maintaining structural integrity. Through careful consideration of load dynamics, material properties, and practical applications, our HDPE pallets set new standards in industrial material handling.

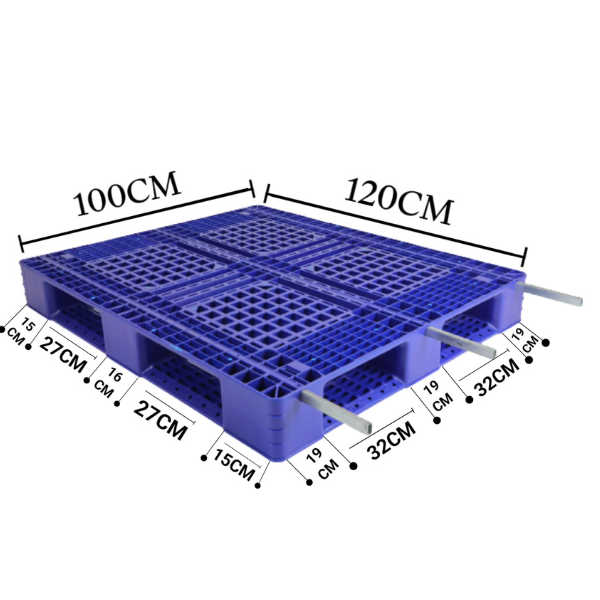

The flagship industrial pallet demonstrates sophisticated entry-point engineering through precise dimensional control. This model features carefully calculated spacing intervals that optimize load distribution while ensuring maximum accessibility. The primary spacing intervals of 27cm work harmoniously with 16cm support zones, creating a balanced framework for heavy-duty applications. Secondary spacing at 32cm intervals, reinforced with 19cm support sections, provides additional stability for varied load configurations.

The uniform 15cm height clearance across all entry points ensures consistent forklift access while maintaining structural integrity. This standardized height has been determined through extensive testing and real-world application data, providing optimal clearance for various handling equipment while preserving the pallet's load-bearing capacity.

Strategic support placement at critical stress points represents a crucial engineering achievement. Each support zone has been positioned to maximize load distribution while minimizing material usage. The SABIC HDPE material optimization further enhances these design elements, providing superior durability and performance under demanding conditions.

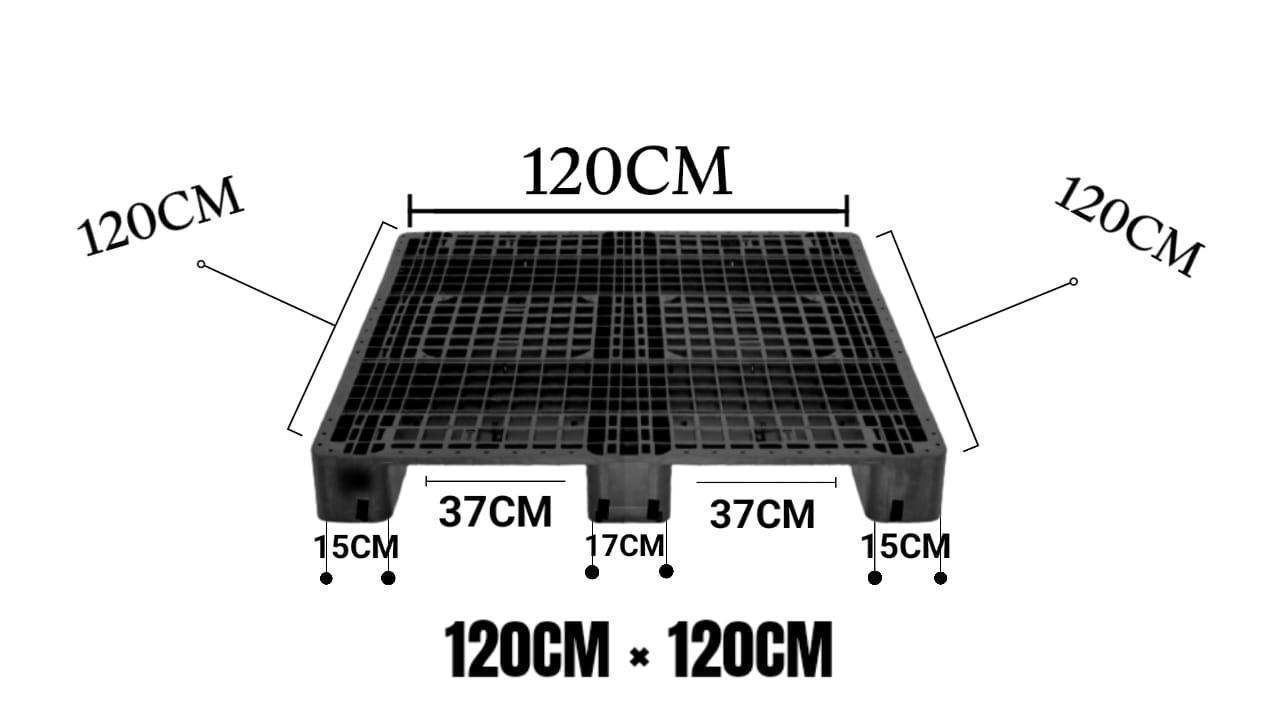

The heavy-duty model showcases an advanced entry configuration designed for maximum load capacity. Primary support spans of 37cm incorporate 17cm reinforcement zones, creating a robust foundation for exceptional weight distribution. This configuration allows for optimal material utilization while maintaining superior structural integrity.

Secondary support features 26cm spans with 34cm lateral bracing, providing enhanced stability for heavy loads. The 15cm standardized clearance height maintains consistency across our product range while accommodating the increased load requirements of this model. Enhanced structural support for maximum loads is achieved through strategic material distribution and reinforced stress points.

The strategic corner reinforcement system represents a crucial engineering advancement, protecting high-stress areas while maintaining optimal weight distribution. This design element proves particularly valuable in high-throughput environments where impact resistance and durability are paramount.

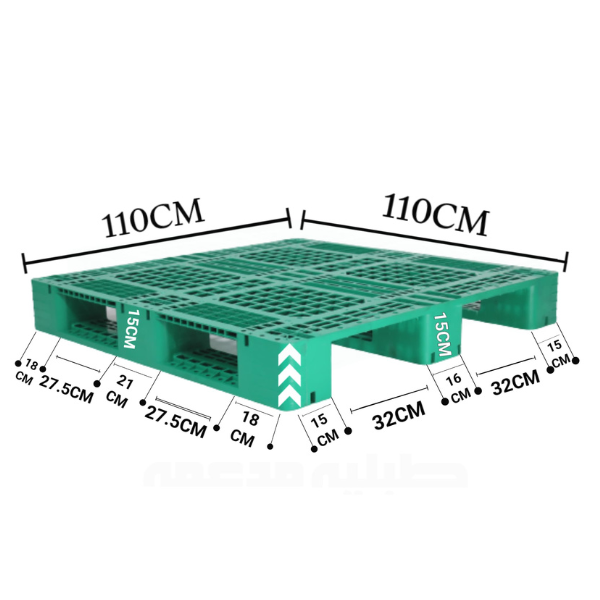

Our innovative compact solution introduces advanced entry system features designed for versatile applications. The entry spacing of 27.5cm incorporates directional indicators, facilitating proper alignment and handling. Support zones at 21cm and 18cm intervals create a balanced framework for optimal load distribution.

The visual guidance system represents a significant advancement in pallet design, incorporating intuitive markers for proper alignment and handling. This feature enhances operational efficiency while reducing the risk of handling errors. The consistent 15cm height clearance maintains compatibility with standard handling equipment while ensuring structural integrity.

The 32cm secondary support spacing provides additional stability for varied load configurations. This spacing has been optimized through extensive testing to ensure maximum performance across different applications while maintaining the compact form factor.

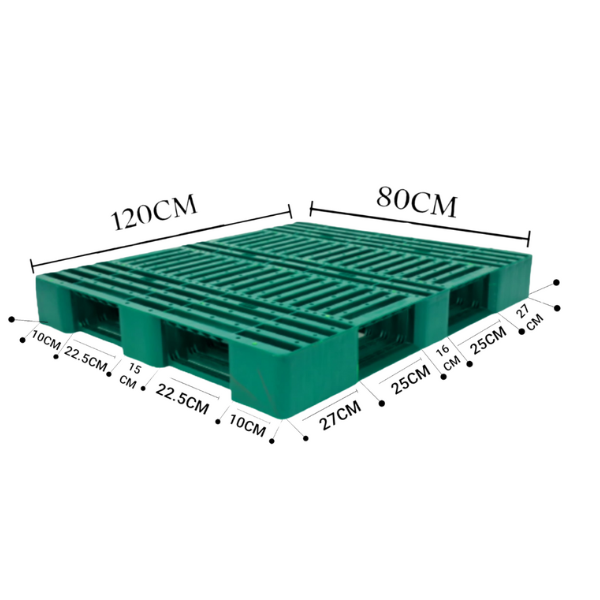

The Euro-standard model exemplifies international compatibility through precise engineering. The 120cm x 80cm dimensions conform to European logistics standards while incorporating advanced structural features. Primary entry points at 22.5cm spacing work in concert with 25cm support zones and 27cm edge reinforcement to create a robust load-bearing platform. The variable height clearance of 10-15cm provides flexibility for different handling equipment while maintaining structural integrity.

At Mohammed Nasser Al Furidi Plastic Industries Factory, our ISO 9001:2015 certified manufacturing process ensures superior load distribution through advanced engineering. The ventilated grid pattern visible across all models facilitates optimal weight distribution while providing essential airflow. Each support point has been strategically positioned to create an integrated network of load-bearing zones.

The reinforced corners feature enhanced material concentration at high-stress points, providing superior impact resistance during intensive handling operations. The integrated support channels create a sophisticated network for distributing dynamic loads across the entire pallet surface. This advanced material distribution system ensures consistent performance under varying load conditions.

The dimensional specifications across all models demonstrate sophisticated engineering for maximum efficiency:

- Precise 27cm entry spacing with 16cm support zones

- Secondary reinforcement at 32cm with 19cm intervals

- Uniform 15cm height clearance for consistent access

Heavy-Duty Model (120x120cm):

- Enhanced 37cm primary spans with 17cm reinforcement

- Strategic 26cm corner support with 34cm lateral bracing

- Standardized 15cm clearance for operational consistency

- Optimized 27.5cm entry points with directional guidance

- Balanced support zones at 21cm and 18cm intervals

- Visual alignment system for enhanced efficiency

Our ISO 9001:2015 certified facility maintains rigorous quality control measures, ensuring consistent performance and reliability across our entire range of industrial pallets.

Al Furidi's plastic pallets meet diverse international standards:

- European Standard EN 13698-1:2003 for Euro pallets

- ISO 3676 compliance for global markets

- ISPM 15 certification for international trade

- Regional quality certifications for specific markets

The facility produces pallets with comprehensive specifications:

- Temperature stability range: -25°C to +60°C

- Static load capacity: up to 5000 kg

- Dynamic load capacity: up to 1500 kg

- Racking capacity: up to 1000 kg

Al Furidi's manufacturing facility ensures global reach through:

- Multiple pallet sizes for international markets (1200x1000mm, 1100x1100mm)

- UV-stabilized HDPE construction for varied climates

- Food-grade material compliance for worldwide standards

- Enhanced durability for international shipping

Comprehensive global support includes:

- Technical documentation in multiple languages

- International quality certifications

- Customized solutions for regional requirements

- Global logistics coordination

Through these capabilities, Al Furidi maintains its position as a leading manufacturer serving diverse international markets with premium plastic solutions.

For detailed specifications and customized solutions tailored to specific industrial applications, contact Mohammed Nasser Al Furidi Plastic Industries Factory through our website: https://alfuridiplast.com/

Your email address will not be published. Required fields are marked *